place the following demands on the system, bearing/seal and lubrication. The solutions shown are examples.

Warehouse

- Material Rings and rolling elements – Through-hardening standard materials

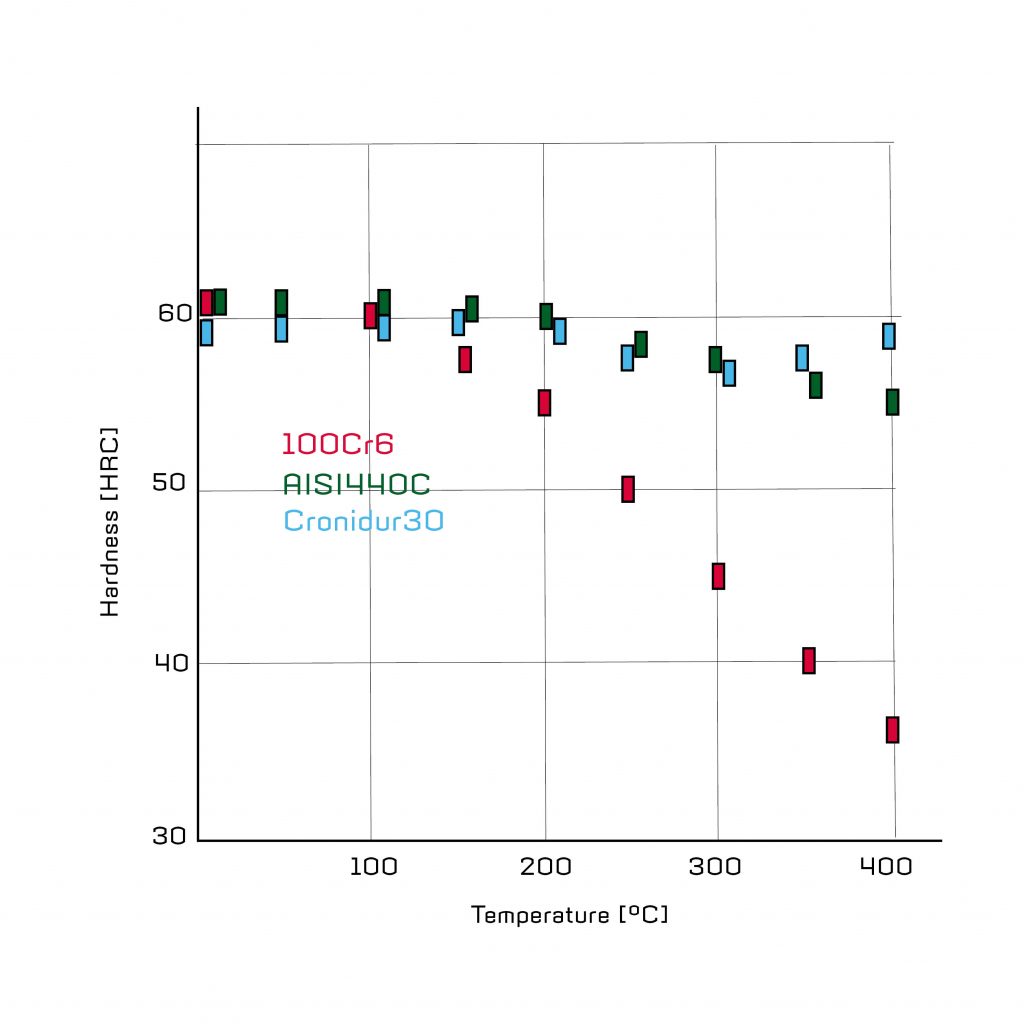

- Rolling bearings are heat stabilized after hardening, usual values for small and medium-sized bearings are 120 (S00) – 150 °C (S0 or SN), for larger bearings made of high-performance steels 200 °C (S1). With these settings, the target hardness of the rings of at least 58 HRC is achieved. Higher heat stabilization (S2 – 250 °C / S3 – 300 °C) reduces the hardness and thus the achievable service life.

- If bearings are used in the area above the heat stabilization temperature, the structure will subsequently change. The result is dimensional changes and, in the worst case scenario, cracks

- The overview in the following table applies to S00 and S0 stabilized bearings, S1 stabilized bearings (e.g. spherical roller bearings from premium manufacturers) have full performance at 200 °C. The temperature factor reduces the dynamic radial load rating Cr or axial load rating Ca.

- The use of classic martensitic rolling bearing steels at temperatures above 250 °C – 300 °C is critical and only recommended for secondary applications, such as kiln car bearings. Above 300 °C, these classic steels become too soft

-

Nachsetzzeichen (Suffix) max Betriebstemperatur Temperaturfaktor S00 120 1

S0 150 1

S1 200 0,9 S2 250 0,75 S3 300 0,6 - Special bearing materials for high-temperature applications include AISI 440C (X105CrMo17 – 1.4125), which can be used up to 500 °C and has a hardness of 56 to 58 HRC. This means that the rings and rolling elements retain the necessary hardness for a long service life. The steel is readily available and relatively inexpensive. Cronidur 30 (X30CrMoN15 1–1.4108) is mainly used as a high-performance steel and maintains a hardness of around 60 HRC up to 500 °C. Some dimensions are readily available. Some dimensions are readily available, but Cronidur 30 is around 10 times more expensive than 100Cr6 (1.3505)

- Bearing clearance

- Due to high temperature differences between the inner and outer ring, larger bearing clearance classes are usually selected

- In bearings with slow speeds and very high temperatures, such as in kilns, the bearing clearance is greatly increased (multiple times C5)

- Solid lubricants require higher clearance classes to avoid blocking of the bearing

Seals

- Sealing variants

- Z Cover discs made of sheet steel are temperature-resistant

- RS seals are usually made of NBR and can be used up to 100 °C

- RS gaskets made of other materials work up to approx. 200 °C, above this temperature abrasive gaskets are no longer used.

- WDR (shaft seals) and O-rings are integrated into special bearings, the temperature resistance corresponds to the material used for the WDR

- Laminar rings and laminar ring packs are often used in cylindrical roller bearings, which are temperature-resistant

- Materials for elastomers (RS / O-ring / WDR)

-

Werkstoff ISO 1629 Basis Elastomer Handelsnamen Einsatzbereich NBR Nitril-Butadien-Kautschuk Perbunan® -25°C bis +100°C FKM Fluor-Kautschuk Viton® -15°C bis +200°C HNBR Hydrierter Nitril-Butadien-Kautschuk Therban® -15°C bis +150°C ACM Polyacrylat-Kautschuk Nipol® -20°C bis +150°C EPDM Ethylen-Propylen-Dien-Kautschuk Keltan® -40°C bis +140°C

Lubrication

- Grease (DUROLUB G)

- A general rule of thumb for mineral oil is that above 70 °C, for every 10 °C increase in temperature, the service life of the oil is reduced by half -> at higher temperatures and standard lubricating greases (mostly mineral oil / lithium (complex) soap), the service life of the grease drops rapidly away

- Modern high-temperature greases for very high operating temperatures are therefore based on synthetic, temperature-stable base oils such as PFPE / ester oil and thickeners made of polyuria and / or PTFE. These can be used up to 260 °C and sometimes more.

- DUROCOMP SLC or compound lubrication based on graphite and/or MoS2

- Self-lubricating bearing compounds are introduced into the bearing and then thermally treated. When hardened, the compound lies in the storage space and continuously releases lubricant to the surrounding rotating rings and rolling elements. DUROCOMP can be used for continuous temperatures up to 350 °C and peak temperatures up to over 500 °C

- All self-lubricating compound solutions are consumable lubricants and are only suitable for slow speeds. If the solid is used up, the bearing fails

- There are no calculation methods for solid lubricants; the service life is an empirical value

- DUROCOMP is an extremely high quality and expensive solution. We use these primarily for highly critical applications in vacuum or with radioactivity. This solution is too expensive for normal applications, for example in roller tables in steelworks.

- For DUROCOMP please contact us

- Bearings with graphite cages

- The normal cages are replaced by ones made of graphite compound. These also function similarly to DUROCOMP up to a maximum of 350 °C, but the clearance between cage and rolling element increases in advanced operation.

- Pastes and solid lubrication

- cheaper versions based on graphite and MoS2. These are applied dry or as a paste.

- In combination with polyglycol oil, solid lubricants can be introduced into the bearing. Here the bearings are run in at +200 °C over a longer period of time. The polyglycol oil evaporates and the solid lubricant is applied in a thin layer to the raceways.

- These lubricants can be renewed.

Coatings

- Phosphatizing, mostly manganese phosphate, are often used for kiln car bearings, increase the adhesive force of the lubricant and improve the running properties.

- DLC coatings are applied at low coating temperatures of up to 200 °C, are temperature-resistant up to 350 °C and can be customized as a coating system to meet specific requirements.

- Modern, self-lubricating tribological coatings can be applied on the basis of DLC. These can also be combined with DUROCOMP