are primarily an issue for lubrication and seals. Common applications down to minus 40-50 °C are covered with standard ring / rolling element materials.

Lubrication

Low temperatures do not destroy greases, but make them stiff. Slippage occurs when the bearings start up, resulting in noise and wear. The grease is quickly heated by the flexing work during operation and thus reaches its lubricity. If temperatures are constantly low, for example in cold stores, this does not work sufficiently.

Mineral oils are hardly suitable for low temperatures; PAO and diester oils with a low base oil viscosity are used. The polymer lubrication DUROLUB DL32 is excellently suited for low temperatures.

As a rule of thumb, the minimum temperature specified by the grease manufacturer should be at least 20 K lower than the expected operating temperature.

Compatibility with the sealing materials must always be checked.

Seals

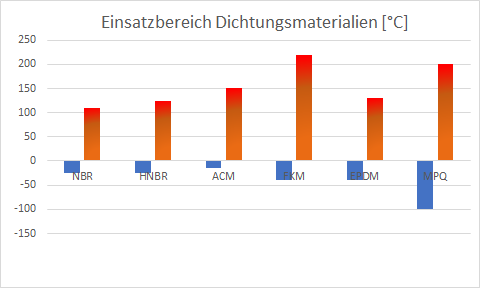

Standard seals, usually made of NBR / HNBR (nitrile butadiene rubber) can be used down to a maximum of -25 °C, ACM (polyacrylic rubber) down to -15 °C. FKM (fluorinated rubber – e.g. Viton) is suitable for temperatures down to minus 40 °C, EPDM (ethylene propylene diene rubber) down to minus 40 °C and MPQ (silicone rubber) down to minus 100 °C.

The seal must be matched to the lubricant and the environment.

The temperature values below may vary slightly depending on the manufacturer and additive content of the polymer.