back to DUROLUB DL general information

Variants / Base oil / Designation (suffix)

The base oil is a universally applicable synthetic oil, also suitable for the food and pharmaceutical industries. It fulfills the CLP requirement in accordance with DIN51517 and has NSF/H1 approval for lubricants where occasional contact with foodstuffs cannot be ruled out.

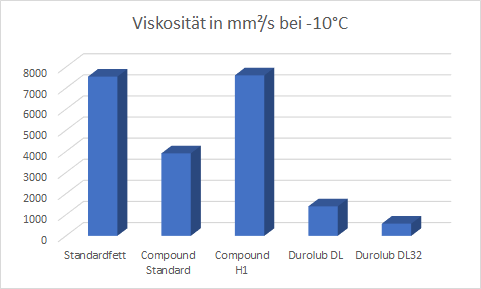

The high viscosity index VI of the synthetic oil allows a wide temperature range of use. DUROLUB DL retains sufficient viscosity at higher application temperatures, but the base oil does not thicken at low temperatures.

Special features:

- Optimum protection against wear

- High resistance to oxidation and ageing

- Very good corrosion protection capacity

- Extended temperature application range compared to mineral oils

- Neutral towards elastomers and plastics

We fill based on the viscosity at 40 °C:

- Suffix DL – standard variant for ball bearings

- Viscosity 68 mm²/s

- Viscosity index VI 153

- Operating range from -40 °C to +100 °C (recommended max. temperature <85 °C, limit due to compound / base oil up to 120 °C)

- Suffix DL32 – special version especially for low-temperature applications

- Viscosity 32 mm²/s

- Viscosity index VI 130

- Application range -50 °C to +100 °C (recommended max. temperature <85 °C, limit due to compound / base oil up to 120 °C)

- Suffix DL150 – standard version roller bearings

- Viscosity 140 mm²/s

- Viscosity index VI 160

- Application range -35 °C to +100 °C (recommended max. temperature <85 °C, limit due to compound / base oil up to 140 °C)

- Suffix DLSxx – special version for deviating base oils

- Applications with special requirements for the base oil, for example applications in vacuum

Speed guide values

After filling and thermal treatment, DUROLUB DL hardens and rotates with the cage. This leads to a reduction in the speed limits.

The limit values below are to be understood as guide values at an ambient temperature of 20 °C; at maximum speed, the bearing heats up by around 60 °C.

The actual achievable limit values are often higher, but must be tested in the application. The limit speed can vary between different makes and designs, especially the cage.

Sheet steel cages are particularly suitable. Polyamide (PA) and brass cages vary greatly due to the different designs of the individual manufacturers.

Speed parameter ndm = dm (mean bearing diameter dm = D (outside diameter [mm] + d (bore [mm]) x 0.5) x n (speed [min-1])

Limit speed ng [min-1] = ndm/dm at 20°C ambient temperature

| Bearing type | speed characteristic (guide values) |

|---|---|

| Deep groove ball bearing with steel cage | ndm 300.000 |

| Deep groove ball bearing with PA cage | ndm 50.000 |

| Deep groove ball bearing double row | ndm 40.000 |

| Angular contact ball bearing with steel cage | ndm 150.000 |

| Angular contact ball bearing with PA-cage | ndm 50.000 |

| Angular contact ball bearing double row | ndm 40.000 |

| Self aligning ball bearing with steel cage | ndm 150.000 |

| Self aligning ball bearing with PA cage | ndm 50.000 |

| Cylindrical roller bearing with steel cage | ndm 150.000 |

| Cylindrical roller bearing with PA cage | ndm 50.000 |

| Tapered roller bearing | ndm 50.000 |

| Spherical roller bearing | ndm 40.000 – 80.000 |

| Insert bearings (UC, Y-type) | ndm 50.000 |

| Needle roller bearing | ndm 50.000 |

| Full complement cylindrical roller bearing | ndm 50.000 |

| Yoke type track roller bearings / supporting roller bearings | ndm 50.000 |

Maximum expected speed (guide values) depending on the ambient temperature

If DUROLUB DL filled bearings are used at ambient temperatures above 20 °C, the limiting speed ng is reduced by a factor fT.

ngred = ng x fT

| Ambient temperature | Factor fT |

|---|---|

| 20°C | 1 |

| 30°C | 0,8 |

| 40°C | 0,7 |

| 50°C | 0,55 |

| 60°C | 0,35 |

Load ratings / dimensions / tolerances / bearing clearance

These remain unchanged from the basic bearing. Please refer to the respective manufacturer’s catalogues.

Bearing friction

The bearing friction increases slightly by one constant when filled with DUROLUB DL, the basic friction behaviour corresponds to the selected bearing type.

Maximum application temperature

DUROLUB DL Compound can be used for short periods up to 100 °C; operating temperatures below 85 °C are recommended. The base oils used are synthetically produced, resulting in a significantly longer oil service life compared to mineral oil-based greases, especially at higher operating temperatures.

Low temperature application

DUROLUB DL32 can be used down to minus 50 °C

At temperatures around and below freezing point, oils thicken very quickly. Due to the high viscosity, the load-independent frictional torque caused by the lubricant increases significantly. This results in high energy costs during cold starts and in operation at low ambient temperatures.

Assembly

If the bearings need to be heated for mounting, the use of inductive heating devices is recommended. Heating plates or heated oil baths are not suitable. Heat to a maximum of 120 °C for mounting.

Colour DUROLUB DL

DUROLUB DL is coloured white or blue depending on availability, the colour has no influence on the function of the compound or the base oils. Special colour requests must be defined when ordering and sometimes require a minimum order quantity.