Dust / dirt and contamination are frequent companions in both industrial and private applications. Ingressing dirt particles destroy the lubricating film, which is only approx. 1 µm thick during operation.

Subsequent cleaning with a high-pressure cleaner or spray water washes the grease out of the bearings, resulting in premature bearing failure.

DUROLUB is introduced into the free space of the bearing, where it forms a solid polymer with a large number of oil-impregnated cavities after thermal treatment. These release the oil to the raceway and rolling elements as required – always just as much as is needed for optimum lubrication.

DUROLUB cannot be washed out, its solid body supports the seals, splash water cannot push seals inwards.

DUROLUB base oils are always based on synthetic PAO oils. These cost several times more than mineral oil, but have many advantages, very similar to those of synthetic long-life oils for engines. DUROLUB oils are so-called H1 oils. For this group of oils, contact with food cannot be ruled out.

Link – Detailed information about DUROLUB and Link – Technical details DUROLUB

Bearings for mountain bikes

Bearings in wheel hubs, pedals, steering columns or in the frame run many times longer with DUROLUB.

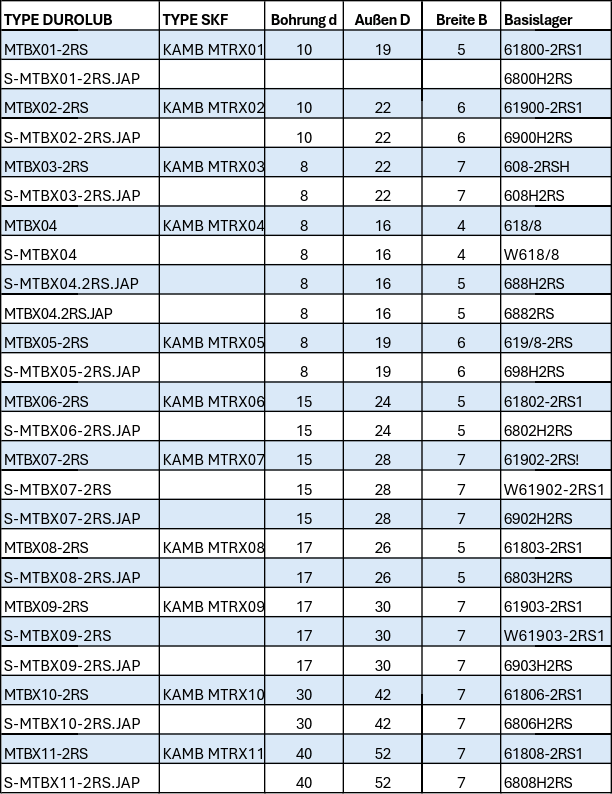

The following list contains standard bearings. If you cannot find the bearing you need, simply contact us. We will manufacture your customised bearing in the shortest possible time.

We prefer to fill SKF bearings, but there are excellent Japanese manufacturers for the types used in mountain bikes. These are characterised by improved seals and rust-free rings. This also prevents ugly traces of corrosion and premature failure.

Wheel bearings / roller bearings for trailers

Roller bearings filled with DUROLUB also work perfectly in wheel bearings for trailers, especially in boat trailers used for slipping.

The service life of the wheel bearings is multiplied and bearing washout is largely prevented.