Current-insulated rolling bearings and components

Electrical discharge machining is a well-known issue in the rolling bearing industry. Every damage catalogue of the renowned rolling bearing manufacturers contains the typical characteristics after a current passage:

- Microcraters are only a few µm in size and are clearly visible under a microscope. To the naked eye, the track appears matt and grey. Microcraters are caused by localised high temperatures in the area of the contact zone, the material melts. Microcraters are the primary damage

- Ripple formations or washboard effects always appear at right angles to the track. These are caused by mechanical vibrations when rolling over the craters and are therefore consequential damage to the microcraters

- Black colouration of lubricants is caused by localised high temperatures. These oxidise the lubricant, change the composition, oils and components burn or coke. The lubricant initially reduces its service life until the lubricating effect fails completely. In the final stage, the lubricant is discoloured black and hardens

Solutions against the passage of current

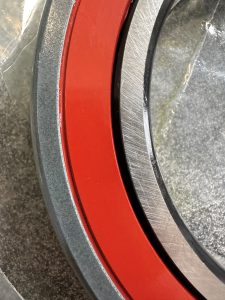

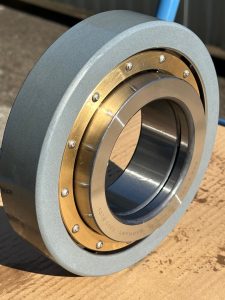

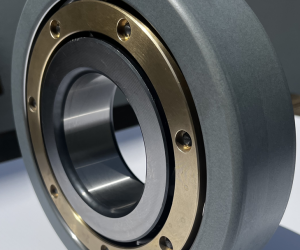

Ceramic coating of the outer ring or the inner ring

These are available in various layer thicknesses and are a ready-to-install solution. All tolerances of the bearing remain the same, no changes to the adjacent construction are necessary

Ceramic coating of the conversion parts

Sometimes it is more cost-effective to coat the rebuilt parts. These are given the same coating that is used in the rolling bearings.

Hybrid bearing

consist of rings made of rolling bearing steel, which are manufactured with ceramic rolling elements, usually made of silicon nitride Si3Ni4. The hybrid solution is generally more economical for smaller bearings.

Click here to go directly to HYTEC hybrid bearings

DUROCOAT DC77 – Coated rolling bearings against current passage

The rings to be coated are pre-machined so that the desired coating thickness can be applied. THB is not limited to a standard program; DC77 can be applied to almost all radial and axial bearing types and sizes.

The production takes place either

- as reworking of the ring to be coated. This is completely independent of the manufacturer of the base layer

- as a series product for larger quantities. The ring to be coated is pre-machined at the factory

General technical / qualitative features

- All tolerances remain the same and are 100% checked. The bearings are ready for installation and no changes to the adjacent construction are necessary

- All coated rings are then sealed and are resistant to moisture and wetness

- 100 % testing of dielectric strength and electrical resistance after coating

- The system + employee details are recorded for each batch

- Further documentation or serialization, including documentation per ring, is possible. We will be happy to offer these after notification of the desired parameters

- The color of the coating is medium grey, white is possible on special request (suffix W)

Dimensions

- Minimum inside diameter: dmin = 80 mm

- Outer diameter Dmax = 1,200 mm, with prior component testing up to Dmax = 1,800 mm using the plasma process

- Outer diameter Dmax = 5,000 mm / max. 25 tonnes are possible using the flame spraying process

- Width or height are usually not critical

Standard coatings DC77 and D77-1

DC77AR (outer ring) / DC77IR (inner ring)

- Coating thickness: ~ 150 µm

- Breakdown voltage: 3000V DC, max. operating voltage

- Electrical resistance: min: 600 MOhm(T < 40 °C / rH <60 %)

DC77-1AR (outer ring) / DC77-1IR (inner ring)

- Coating thickness: ~ 250 µm

- Breakdown voltage: 3000V DC, max. operating voltage

- Electrical resistance: min: 800 MOhm(T < 40 °C / rH <60 %)

Other coating thicknesses

- up to max. 300 µm possible on request

- 500V or 1000V coatings are not manufactured

Current-insulated abutment parts

The technical and quality specifications for rolling bearing rings can be used for any other parts around the bearing. Therefore, it can be more efficient to coat shafts rather than inner rings of bearings.

We always recommend a component check before submitting an offer.

Packaging / Labelling / Marking

The bearings are not subsequently marked. Labelling on the coated ring is therefore no longer legible.

We pack in the original packaging of the bearing manufacturer and mark with a sticker.

Designations of other manufacturers / Cross-reference

Only the following manufacturers offer similar systems with their protected designations:

SKF – Insocoat Suffix VL0241 / VL0246 / VL2071 / VL2076

FAG/ INA / Schaeffler – Lubtect Suffix J20AA