DUROLUB G – The grease lubrication

With the DUROLUB G series, we offer ready-to-fit rolling bearings with high-performance lubricant.

Rolling bearings greased at the factory usually contain an economical universal grease, often based on lithium / mineral oil. This is sufficient for many applications.

Under critical conditions such as high/low temperatures, high speeds/loads, oscillating applications and fluctuating ambient temperatures, the service life of these greases quickly reaches its limits.

The achievable bearing service life cannot be reached due to suboptimal lubrication.

DUROLUB G – The lubricating greases

Just like the rolling bearing manufacturers, all of whom do not produce greases, we use greases from well-known manufacturers such as Shell, ExxonMobil, Chevron, Castro, Bechem, DuPont, Fuchs, Klüber, Lubcon, Dow-Corning, Kyodo-Yushi, Total, etc.

The greases used / sold / recommended by premium rolling bearing manufacturers are tested and approved on test benches. Behind the abbreviations or marketing names are the above grease manufacturers and their products.

It can be complicated, but it doesn’t have to be!

Our database contains over 400 different greases that are approved by rolling bearing manufacturers such as SKF / FAG / INA / NTN / NSK / BARDEN / NMB. We prefer to use these greases or similar greases from the group of manufacturers with approvals.

The huge selection covers virtually all applications, and with the DUROLUB G series, all of these greases are also available for sealed, ready-to-install bearings, even in small quantities.

Delivery times / minimum quantities

We often start with small order quantities. This means that extensive tests can be carried out on site, even with different lubricating greases.

The greasing itself is carried out within a few days. The decisive factor is usually the delivery time of the bearing or grease

(due to the minimum shelf life of the grease, we only keep standard versions in stock). For small quantities, we charge the minimum quantity of grease

Quality and price of rolling bearing greases

There is a wide range of different products on the market. Generally, greases consist of around 80 % base oil, a thickener and often additives. If necessary, additional solids are added to the grease.

Originally, only mineral oils were used and mixed with various thickeners and additives depending on the area of application.

Mineral oil, within its application limits, is still the first choice today due to its good tribological properties and favourable price. Modern synthetic oils allow the properties of the base oil to be precisely adapted to the application. Almost all high-performance greases therefore contain synthetic oils.

Greases with extremely long service lives (low ageing/oxidation), high and very low application temperatures, extremely smooth or low-noise running or high-speed greases and greases for the food industry can be optimised with synthetic oils.

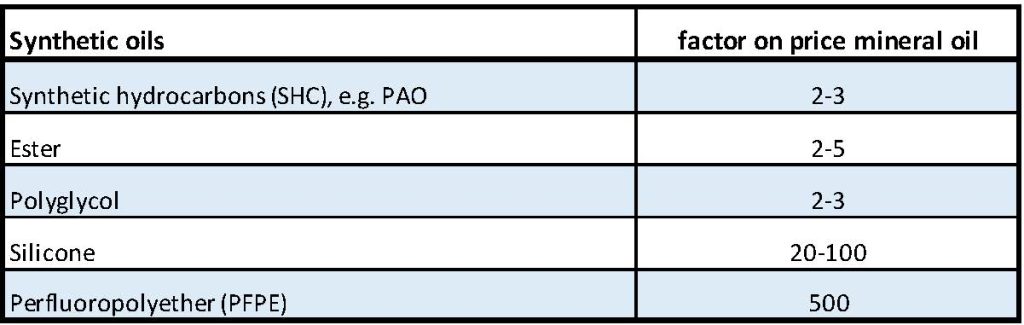

Quality has its price – synthetic oils are always more expensive than mineral oils, in extreme cases up to 500 times more expensive. Lubricating greases for extreme applications can therefore cost well over €1,000 per kilogram. However, the use of expensive greases usually pays off quickly – operating and maintenance costs are reduced, and the environment is protected.

Typical applications for special greases

- High and low temperatures with mineral oils

- At higher temperatures, the viscosity decreases, the oil becomes thinner and ages much faster. This marks the essential application limit for mineral oil, which should only be used permanently up to 70 °C.

- The mineral oil quickly loses its operating viscosity as the temperature rises and for every 10 K higher operating temperature, half of the grease’s service life is lost.

- The remaining grease service life at 90 °C is still around 25% of that at 70 °C.

- Conversely, mineral oils become very viscous at low temperatures and therefore lose their lubricating properties and consume a lot of energy due to the high friction, e.g. in conveyor lines of cooling systems.

- High and low temperatures with synthetic oils

- Synthetic oils can be used to reliably lubricate rolling bearings over a wide temperature range. Ester oils are often used at high temperatures, while alkoxy fluorine oils such as PFPE achieve the longest service life at continuous temperatures above 150 °C. PTFE is often used as a thickener in these greases.

- For low temperatures, greases based on PAO (polyalphaolefin) or diesters are used, thickened with lithium soaps.

- The viscosity behavior of the oil over a temperature range is described by the viscosity index; the higher this value, the better the oil is suited for use at different temperatures.

- VI – 100 describes the viscosity behavior of the best mineral oil, in the diagram compared to a silicone oil with VI – 500

The upper service temperature specified for greases should be treated with caution. It only needs to run for 100 hours at this temperature to pass the test.

In order to achieve a good grease service life, the upper and lower service life values of the grease should be significantly higher (or lower) than the operating temperature, but at least 20-30 K.

- High speeds

- The speed characteristic of a grease is made up of the average bearing diameter dm [mm] and the speed [min-1] and is specified as ndm or n.dm

- The level of the speed characteristic depends largely on the base oil type, the viscosity and the thickener system. The oil should flow quickly and constantly into the contact zone without being thrown out of the bearing

Labelling

We label the outer packaging of the layer with a sticker and the number of the special grease / filling level if different from the standard and indicate the NSF H1 suitability